I bought a new 10" chuck at the January 2006 Cabin Fever show up in

York, PA, it is stamped "Made in England"- perhaps a

Pratt-Bernerd. Either way its not rusty nor are the jaws loose

like my old chuck. It took a couple months to buy a couple

unmachined backplates on which to mount the chuck.

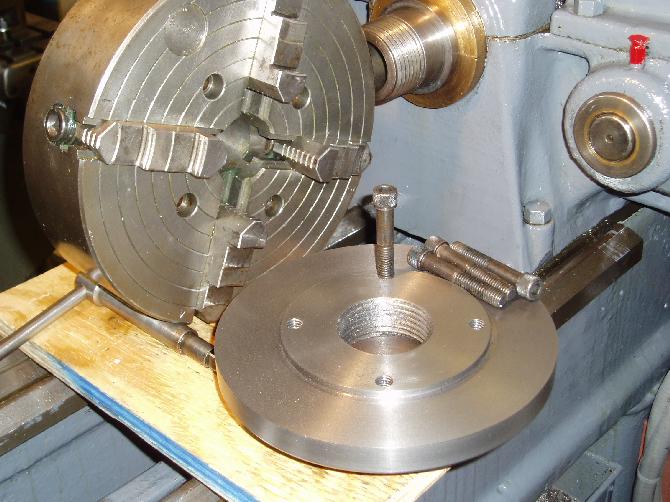

But first I have to machine the backplate (unfortunately I lost the

pics of machining the spindle bore... bummer). Here I'm starting

to face the mounted backplate.

The plate is approx 8" OD, I have to face off about .192 from the

outside 1.5" or so, leaving a 5" diam boss onto which the chuck is

mounted. Makes lots of chips and I got a lot of experience

fooling around with feeds and DOC.

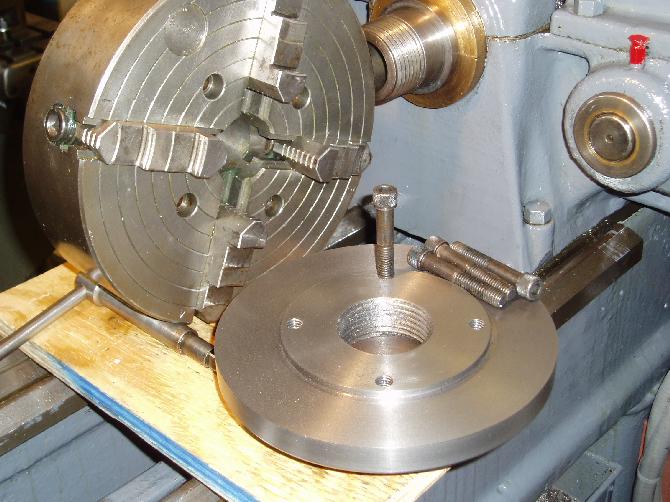

But eventually I got it cut- I wanted size-on-size, but a burr misled

me so I ended up with a running fit... good enough for a first try I

suppose...

And onto the spindle we go;

Naturally none of my chuck wrenches fit, so off to enco to get some that are sort of close-

they don't fit either, so now to anneal, machine & grind one into submission...

;;; eof