Serial # 7-M-3796

In January 2007 I took advantage of an opportunity to get one of these

mills for free. Cleaning & prepping the machine delayed a

number of projects, but its in fine shape and I'm looking forward to

getting it running.

I eventually got it to the patio, removed the table & motor;

My dad came over to help, we got the mill over onto its back, then down

the ramp into the basement. The casting is blocked up with a

length of 2x4, keeping the back end of the spindle from bearing on the

sled.

And down, safe & sound!

Then after a week of stripping & cleaning;

Nichols made several versons of the head, here's a closeup of mine;

February 2007, now painting;

Paint is Sherwin Williams "Hyper Blue". Two coats were applied,

with the addition of an alkyd enamel hardener. 32oz is about

right

for the mill. The paint hides brush strokes relatively well but

tipping the coat about an hour after application helped the finish

considerably. Overall I'm quite happy with how the paint worked

out- it makes the other machines seem drab rather than

understated. We'll see how it stands up to oil & chips.

The Nichols manual specifies "600-W" oil for all the zerks, in this

case

its not viscosity but the name of a manufacturer's brand. Another

Nichols owner traced to an approximately ISO 350 lubricant. I

bought some ISO 220 grease for the spindle, I tried it out, and it

works

fine but makes a mess when the excess is flung clear- so installing a

guard around the pulleys will avoid laying down a racing stripe on

neighboring items. I switched to Vactra #2 on all the sliding members

which is lots easier to clean up.

My mill has the 5-groove pulleys and uses an A59 sized belt.

The motor gearbox was dry but drained clean when flushed with WD40. The

manual mentions a "dipstick" for checking the oil level in the motor's

gearcase, if the tag shown in the manual is missing, the dipstick is

easily found. Locate the air vent between the motor & gearbox. When

facing the output shaft with the vent upwards, the dipstick is the

small

screw seen on the left of the mouth of the vent. There is a gearcase

vent on the right of the mouth. Both are unscrewed for their respective

service. The vent on mine was painted shut, a soft wirewheel cleaned it

right up. I have some DTE Heavy/Med gear oil in there now, which

is thinner than the specified 40W Motor oil- I will get the proper

stuff

in there shortly.

In operation, some oil drips out around the gearcase shaft, so moving

the pulley out 1/8" or so will let it drip clear and not be flung all

over creation. 40W oil is a definite improvement over the DTE in this

case.

I mounted the vfd's speed control pot in the start/stop cluster, should

make tweaking the speed handy.

This shows the jury-rigged vfd & power. The drum switch

connects to the vfd's fwd/rev input. The toggle connects the vfd

output to either the aux outlet or the Nichols motor. The lower

box contains a transformer, diode bridge and relay. The start

button latches the relay on, stop turns it off. The latching

relay

connects the fwd/rev circuit through to the vfd. So, the

start/stop, fwd/rev and speed control work for the aux outlet and the

main motor.

I put the R head onto the mill for a motor & bearing test;

The R head is a bit too big for the mill, it takes up a good deal of

the envelope and is clumsy to tram. A smaller head would be a

better fit, though an R or M head will certainly work.

4/1/2007

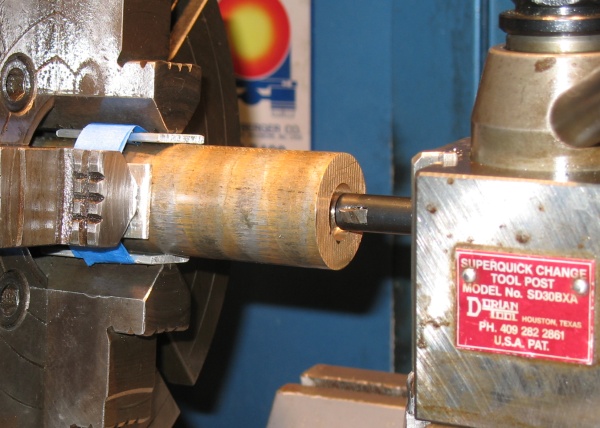

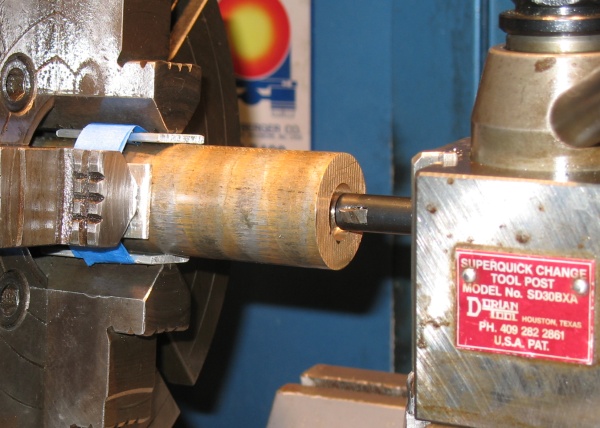

Threaded flange for the y axis nut- the bronze acme nut will thread

into this & be soldered into place, then everything will be turned

& faced to size.

I did the flange first so I could do all the work on the nut in one

setup.

The nut is SAE660- it turned wonderfully. Its a welcome break

from

various bits of mystery metal- one of which I made the flange

from. The step on the nut is an extra .020" finishing allowance

after the flange is screwed on & soldered.

I didn't nail the threads exactly but the fit is pretty good. The

visible face here will be removed by the finishing passes. I

sucessfully single-pointed the internal acme threads (10tpi), using the

y axis screw as a go/no-go gauge.

Showing nut turned for OD w/ grease groove, and flange turned and faced

after soldering. You can see the little band of solder right in

the joint between the bronze & steel. The sludge in the acme

threads is some grease I wiped in to make sure the solder didn't wick

inside.

Parting was nice and smooth.... :)

And here all nice & pretty, looks good so far huh?

And heres what happens when you don't snug the jaws down tight enough

on the dividing head... Only a cosmetic problem, but a drag

nonetheless. Because I lost zero I had to increase the clearance

on the 3rd hole..

And here a test-fit on the y axis screw...

And here, installed. The y axis feed feels quite good. I

think I succeeded in a centering fit, there is no discernable backlash

either. Cosmetics aside I'm quite happy with the new nut.

June 2007

In April myself and two others went shares on a Nichols parts machine,

it took me a while to get their parts shipped out. A minor point

I'd like to stress- when going shares on a parts machine, negiotiate

both the shares of the purchase price and the shipping.

One of my parts was an overarm support. Its an older one with

bronze bushing that was badly wallowed out. I replaced it with a

steel plug bored true to the spindle, into which I'll fit a needle

bearing.

The support clamp is loose on the overarm so it slides as the table is

moved inwards, making the boring head cut the bushing true to the

spindle. It would've been better to push the overarm with an

angle plate, or clamp the support and let the overarm slide, but there

wasn't room to do either.

And a picture of the daughter, taken one evening we spent in the

basement;

Here I finally got to finishing the front face of the arbor

support. Naturally I discovered I left the bore .0015 or so too

small, so at some point I'll have to try and replicate the setup...

12/2007, 1/2008

I had an occasion to repair a Nichols knee gib that was cracked in 3

places. I milled about 1/8" off the back of the gib and fit a strip of

steel of similar thickness. I put a screw in on each side of each of

the 4 bolt holes. Worked like a champ, and the gib is in service now.

There appears to be some tendency for knee gibs to break around the

middle two bolt holes, perhaps due to excessive tightening of the knee

lock.

Having gotten the gib figured out, I reassembled the machine and did the

first job on it. In this case, cutting away the bulk of the webs on an

inexpensive import angle plate. I made a movie of the finish cut on one

of the webs here;

nichols-lever-feeds.mpg

Here's a 5" diameter shell end mill by P&W, very nice- unused, a

bit of surface rust in spots due to poor storage, looking forward to

trying it sometime;

;;; eof