(all photos)

(home)

Although it worked fine in this application, the 16 tooth worm gear on

my old ATW's threading dial was badly worn. Its supposed to be a worm

gear but this one sort of looks like a plain old spur gear that was worn

in. When I got the lathe, the threading dial was very stiff, it may

have never been oiled. I think this caused the excesive wear on the

gear.

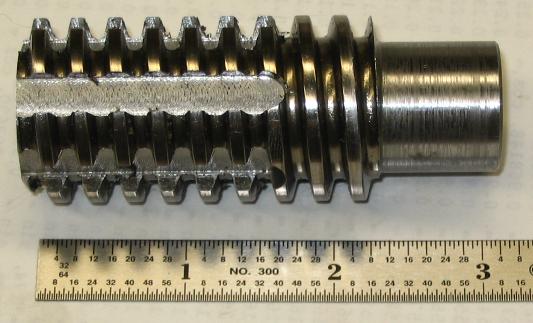

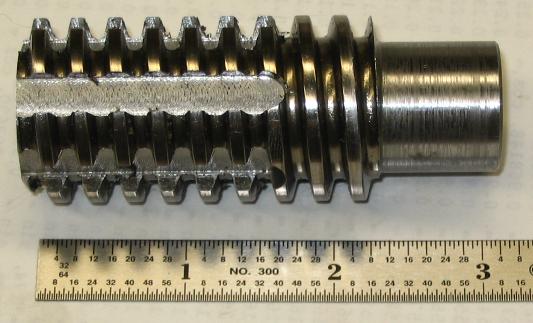

In 2005 I got a length of 4140 1 1/4 - 4 acme rod from

Green Bay Manufacturing.

It was fun to turn the shank, nice 20' long stringy chips. I wasn't

paying enough attention to feeds & speeds to get a good finish.

Since I'm using the hob to cut brass I didn't bother trying to put in

top relief or additional hardening. I should have cut the notches

deeper, but these are enough to cut- though slowly.

In Dec 2006 I finally got around to getting the project going again. I

made a mandrel to mount the blank on the dividing head so I could put in

the gashes that the hob will use to spin the blank while it forms the

teeth later on. Feeds & speeds are improving. :)

I got the blank straightened out too. When I put the bore in I'd

forgotten what happens when you try to put in a bore to size with a

twist drill; hole is neither straight or round. So bore it out, solder

in a plug, drill & bore that to diameter. Then cut away the solder

which got all over everything without messing up the dimensions. I

forgot to put strips of aluminum between the chuck jaws and the gear, so

damaged the gear's finish- no big problem, just sloppy.

And then into the dividing head. I computed a 4 degree lead from

Machinery's Handbook, so approximated that by the scale on the dividing

head. I cut the teeth to the depth of the addendum of the final tooth

profile.

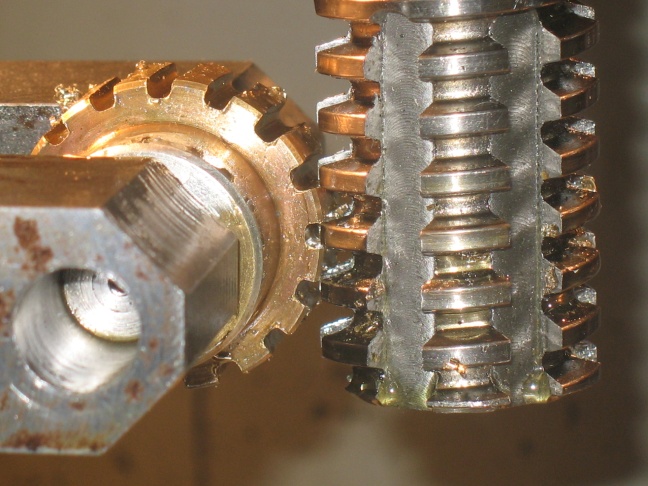

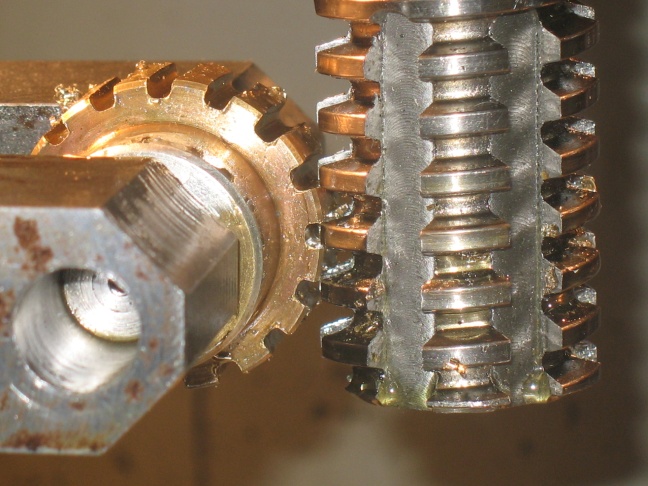

With the gashes in, I set up a jig to hob the gear.

February 2007

I finally got around to hobbing the gear;

I recorded an AVI file of it running,

hobbing-gear.avi

(transcoded to x264, which may help w/ some players)

hobbing-gear.mp4

The lack of relief in the bottom of the thread made finishing slow, and

the 4140 did begin to dull so hardening is in order, even for brass. But

I got decent gear out.

I wasn't confident about drilling the new gear for the taper pin, so put

setscrews in instead. Here is the mounted gear.

And the face of the threading dial after I added some paint on the

background.

;;; eof