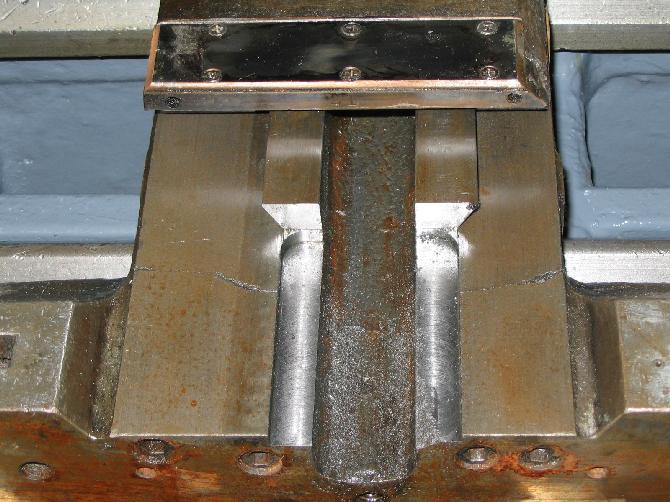

Here is a picture of the broken portion of the dovetails, rear half of

the saddle.

So I get to play like a machinery repair tech...

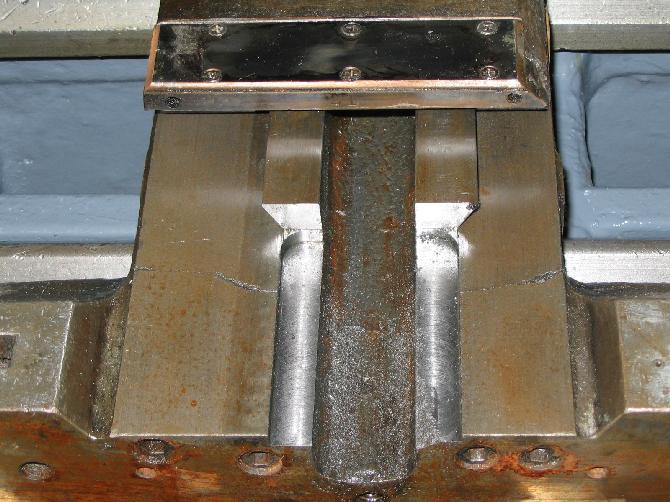

After milling out the broken portions, I moved the saddle back to the

lathe to free up the Bridgeport for the next steps. In the

picture below, the milled out pockets are visible. I had to leave

some of the broken portion on the right-hand dovetail due to proximity

to the capscrew holding the wing to the saddle visible just to the

lower right- milling it clean would have brought the cut very close to

the capscrew head & shank..

The repaired cross-slide is also shown, after soldering with ~2% silver

bearing solder. I'll do a final cleaning and fill voids with JB

weld before painting.

The next step is to prep some new dovetail pieces and screw them down

in the milled out pockets. I'm still debating using

silver-bearing solder vs silver brazing to permanently fix the new

dovetails. While I think about it, I'm going to install the

motor, controls and VFD and get the lathe rolling... :)

Next step was to fit some 1018 stock into the pockets and screw them

down, then the excess is trimmed. I'll cut the dovetails last.

I milled off the excess material all around, then started milling the

dovetails. Naturally the first dovetail cutter was too small, the

second was too large, but the third was Just Right.

The test fits are good, so I deburred and moved the saddle off the

Bridgeport. Next step is to take the dovetail sections off, clean

& prep for soft soldering. If I had an oxy/acetylene rig I'd

braze. OTOH the new sections only support the taper slide,

so they don't need maximum strength.

;;; eof