8/1/2008

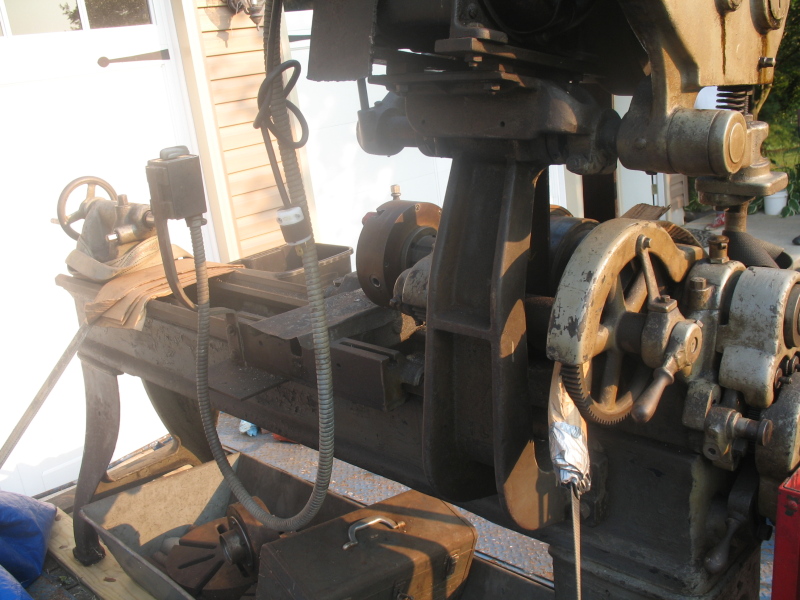

14" American Tool Works lathe

8' overall

no serial # found

circa 1910 - 1920

single backgear headstock

Weight is appox 2000 lbs, perhaps 2500 total w/ all the tooling.

General notes;

- threaded spindle, bronze spindle bearings. measured <= .003"

flex both directions in y and z with DTI against the chuck and a 2'

length of stock in the jaws as a lever, applying moderate force

. Could not measure TIR because

hold-down strap is on one spindle sheave. Specified max spindle rpm is 350, but can be sped up

to 450 without issues.

- Carriage feels excellent in traverse. Lock works well.

Lock handle is non-oem. Interlocks function.

- Compound backlash is < 1/4 turn. Crossfeed backlash is just

under 1/2 turn. I suspect a large component of this is due to

shaft thrust bearings not properly adjusted- some wear is probable

though. Cross-feed nut is not of adjustable type, probably cast

iron.

- Cross-feed dial is excellent, compound dial has cosmetic issues

- Taper attachment does not appear to be present. Thread dial is

present.

- All tooling shown is included. Did not test-fit chucks,

faceplates but I do not doubt those shown will fit. Toolbox below

lathe has about 2" deep layer of HSS, carbide lathe bits. Red box

contains more tooling of unknown type(s) (drawer faces lathe so could

not be opened). Includes rocker toolpost & a large boring bar

holder. I did not see boring bar(s) for it. At least one of

the OEM hex wrenches is also located in the bin w/ the rest of the

tooling.

8" diam 3 jaw, 2piece jaw chuck

8" diam 3 jaw, 1pc jaw chuck

12" 4 jaw chuck

15" faceplate

8 1/2" diam dog plate

steady rest

- Motor is 1PH, could not read plate for HP or voltage.

Presumably 220v (because of the plug) and 1HP as per the legend on the

transmission casting.

- No sign of damage on the visible portions of the gears I could see

without further disassembly; edges of teeth are crisp, no burrs.

- Condition of bed borders on excellent. Belt is tired but will

probably work.

- Lathe is quite dirty, a number of the flip-top gits oilers are

missing and the holes full of crud. Extensive disassembly and

cleaning will be necessary. Modern Gits oilers will fit in the

holes.

- A big issue is the lathe is under a tarp, no other protection from

the elements. Bed is oily but rust will start showing up pretty

soon.

Known terms of sale;

- Lathe is in Urbana MD, just off 270.

- The owner lives in PA, his daughter has the lathe on this trailer in

her backyard. Sale arrangements should be made through the

father. Arrangements for further examination should also be made

through him and his daughter.

- Rather than giving out the phone #'s for the daughter or her father

on the open internet,

please contact me via PM or at gmlathe@comcast.net

for them.

- My ATW lathe which I extensively disassembled and worked on is very

similar to this one, if you have further questions I'd be happy to help.

I'm fairly local to the lathe now, and

could help out picking it up at least.

- I am in no way related to the owner or his family. I am not

brokering nor involved in any way with this sale. I'm just trying

to help find a good home for the lathe.

- The trailer holding the lathe is intended to go back to the owner up

in the Oxford/Kennett Square PA area. He may be willing to drive

the

trailer to areas nearby its current location or up in PA- this will

have to be negiotiated with the owner. Otherwise, the lathe will

have to be picked up at its current location; unloaded off the trailer

and onto the buyer's transport. The daughter does not have any

suitable equipment- a number of rental places operate nearby, a

forklift rental might work out fairly well.

- I saw this lathe on Craigslist where the price was given at

$995. I

don't know how firm the price is.

Photos follow. Additional notes for some photos are included w/

the pictures.

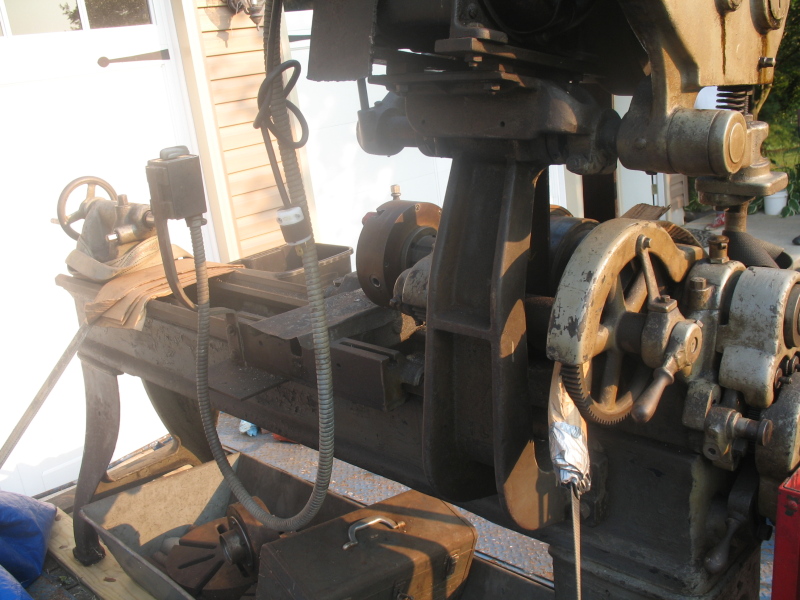

These may be OEM oilers, the bearing caps are tapped for 1/4-18 pipe

threads. Nut for the bolt securing the bull gear

to the pulley is just out of view around the spindle. Backplate

is not OEM for this chuck.

Homebrew carriage lock handle seen here. Carriage lock is robust.

Cross-feed dial is great- compound dial is funky but will work.

Carriage feed pinion does not withdraw from the rack on this size/age

of lathe. Power carriage and cross feed star wheels.

Missing the small bolt used as a threading stop. Top of the apron

is nice and smooth. t-slots are just a bit too small for

Bridgeport hold-down sized nuts, unfortunately. I suspect the

compound micrometer dial is a homebrew.

Some of the usual damage but not excessive. I believe chip shield

is not

OEM.

I felt no obvious scoring or ridge on the outer ways. Inner ways

have some

dings but not bad at all.

Note missing placard on rightmost shifter, should read "Feeds

| Threads". Lathe has a total of 64 feeds/threads arranged

in two sets of 32, just swap a pair of gears on the quadrant arm.

Ranges from 2tpi/.125 feed to 112 tpi/.002 feed.

Rotate this handle to tighten belt- a very handy arrangement.

Sorry this is so out of focus, I had to reach up over to get it at

all.

;;; eof